rayman@raymanpipe.com

0086-538-8997789

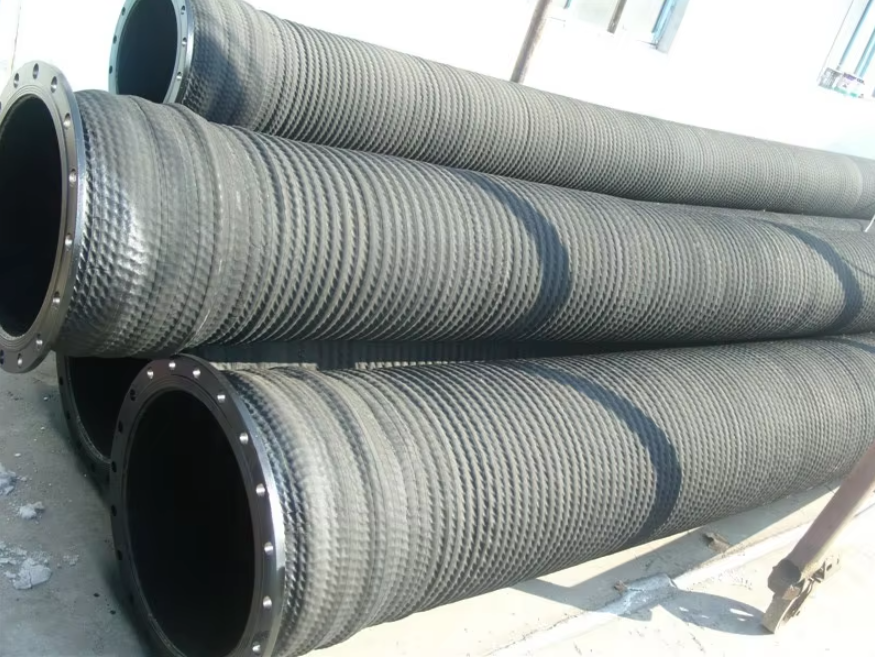

法兰端橡胶软管

法兰端橡胶软管是一种柔性管道连接器,设计用于在配合的管道法兰之间用螺栓连接,特别是带有垫环或短端的HDPE管道系统。通过在两端粘合或机械固定钢法兰,软管提供了可靠的密封,同时提供了灵活性,以适应路线变化、错位、振动和热运动。典型用途包括疏浚排放管线、泥浆和沙子运输、工业用水系统、排水以及临时或移动管道。

典型的法兰端橡胶软管由三层或更多层组成:

1) 内胎:与输送介质相容的橡胶化合物(例如,NR/SBR用于水和浆料;NBR用于油/燃料;EPDM用于热水和风化)。

2) 增强材料:高强度合成织物(聚酯/尼龙)、多层织物和/或钢丝编织物/螺旋,以承受压力和真空。

3) 外罩:耐磨、耐臭氧和耐候橡胶(通常是NR/SBR或EPDM),以防止外部损坏。

4) 端部配件:碳钢或不锈钢法兰(固定式或旋转式),硫化粘合或机械固定;垫片表面符合标准。

制造过程

1) 橡胶的配制与混合;

2) 内胎挤压;

3) 钢筋应用(纺织品/钢材);

4) 外盖挤压或包裹;

5) 法兰固定(硫化粘接或机械锚固);

6) 硫化(高压釜/蒸汽固化);

7) 水压试验;

8) 目视检查和尺寸检查;

9) 标记和包装。