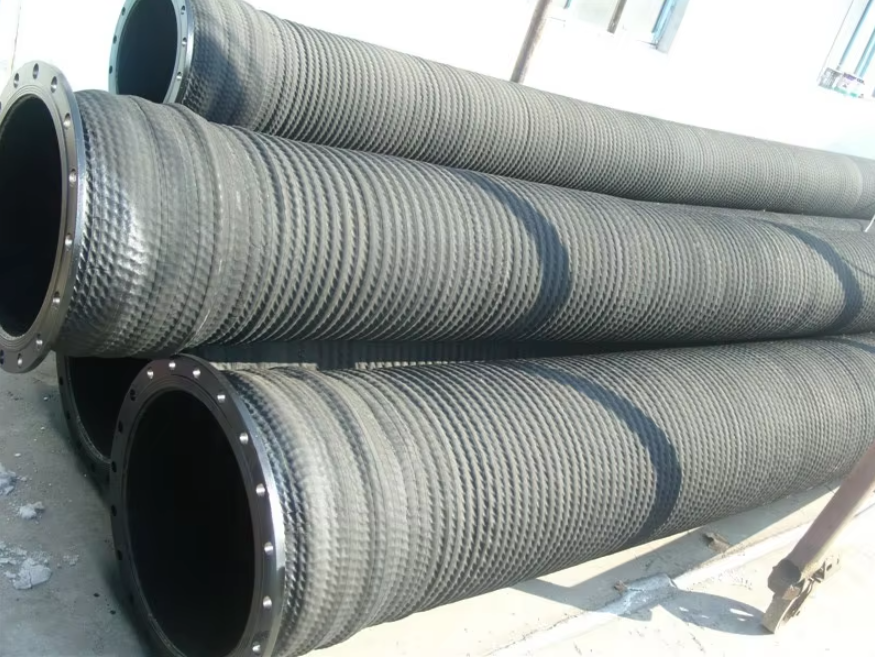

Flange end rubber hose

The flange end rubber hose is a flexible pipeline connector designed to be bolted between mating pipe flanges—especially HDPE pipe systems with backing rings or stub ends. With steel flanges bonded or mechanically fixed to both ends, the hose provides reliable sealing while offering flexibility to accommodate route changes, misalignment, vibration, and thermal movement. Typical uses include dredging discharge lines, slurry and sand transport, industrial water systems, dewatering, and temporary or mobile pipelines.

A typical flange end rubber hose consists of three or more layers: 1) Inner Tube: rubber compound compatible with the conveyed medium (e.g., NR/SBR for water and slurry; NBR for oil/fuel; EPDM for hot water and weathering).

2) Reinforcement: high-tensile synthetic textile (polyester/nylon), multi-ply fabric, and/or steel wire braid/spiral to withstand pressure and vacuum.

3) Outer Cover: abrasion-, ozone-, and weather-resistant rubber (usually NR/SBR or EPDM) to protect against external damage.

4) End Fittings: carbon steel or stainless steel flanges (fixed or swivel type), vulcanized bonding or mechanical retention; gasket face per standard.

Manufacturing Process

1) Rubber compounding and mixing;

2) Inner tube extrusion;

3) Reinforcement application (textile/steel);

4) Outer cover extrusion or wrapping;

5) Flange fixing (vulcanized bonding or mechanical anchoring);

6) Vulcanization (autoclave/steam curing);

7) Hydrostatic testing;

8) Visual inspection & dimension check;

9) Marking and packaging.

Contact: Sophy Gee

Phone: 0086-132-0538-3163

Tel: 0086-538-8997789

Email: rayman@raymanpipe.com

Add: No.279, Longquan Road, High-Tech District, Taian City, Shandong Province

We chat